Reference designators for electrical and electronics parts and equipment

01

Reference designators for electrical and electronics parts and equipment

My attempt is to extol the virtues of following the standards that exist in applying reference designations to electrical/electronic projects and products. Calling upon my decades as an amateur radio operator and as a graduated engineer in the field of analog/RF/microwave circuit design.

Welcome to this article.

My attempt is to extol the virtues of following the standards that exist in applying reference designations to electrical/electronic projects and products. Calling upon my decades as an amateur radio operator and as a graduated engineer in the field of analog/RF/microwave circuit design.

A case in point is the octagon shaped traffic sign. No matter if the sign has on it ALTO, HALT, or STOP, we all know what is meant. If you and I reference, understand, and use the pertinent standards we will have better understanding with less miscommunication.

What I do is reference all the applicable standards together in one place so you don’t have to go searching yourself:

Appendix A is a list of the standards that I have gone by for many, many years. If you are aware of some other additional standard, let me know and we will discuss adding it to the list.

Appendix B is based on IEEE 315 Clause 22, Class Designation Letters, with Clause 22.4, Class Designation Letters: Alphabetical List, being the “official” list of class letters. The IPC has published IPC-2612-1 2010, Sectional Requirements for Electronic Diagramming Symbol Generation Methodology that has an APPENDIX A they call Reference Designations. This is really a list of class letters, mostly from IEEE 315, Clause 22.4, but they have added nonconforming letters. However, there are a few class letters that need to be added because of modern day software and the use of PCB layout programs. Other companies and organizations use their own list or have published lists of class letters from time to time, but there is no need to, just follow the ASME and IEEE standard.

Appendix C is a list of nonconforming class letters. This list can always be added to. See Appendix B for the list of proper class letters to use.

The Unit Numbering Method

The Unit Numbering Method of applying reference designators is explained in ASME Y14.44. Two other methods, namely the Location Numbering Method and the Location Coding Method, are also explained, but they are extensions of the Unit Numbering Method and I, personally, have never seen them used.

A basic reference designation is of the form: LLL#A

Note: All letters are uppercase, no lowercase letters are used.

Where LLL is a class letter(s)–a class letter denotes the class or kind of part and can be one, two, or three letters, but if three class letters the first letter will be an X. E.g. XDS or XAR. See Appendix B Clause 0.4 for the “official” list of class letters.

The # (octothorpe) symbol, or number sign, is a number that starts with 1 and can go as high as needed. Think of it as a serial number.

There may be a suffix letter. “A suffix letter, beginning with A, shall be added to the basic reference designation to identify each portion of a multiple-element part or similar item...” These reference designators, with suffix letters, would of course be shown on a schematic diagram, but only the base reference designation would appear on a parts list (PL). However, you can have a case where the suffix letter is an individual part and would need to be listed as such on the parts list. For example if you have a fuse F# that uses a couple of fuse clips as the fuse holder, then these fuse clips would be reference designated XF#A and XF#B on the schematic diagram and would be listed as such on the parts list.

For a simple one printed circuit board assembly (PBA), a small volt-ohmmeter, or a radio receiver, such as a WWII BC-348 shortwave receiver with point to point wiring, only a basic reference designation is necessary to completely identify each part in the equipment.

“For more complex sets involving two or more units or one or more levels of subassemblies, to completely identify an item within the set, the basic reference designation shall be prefixed with the designations assigned to the subassemblies and the unit incorporating the item”.

Appendix D shows a simple system subdivision, these are often called product structure diagrams. They show how a product is structured or put together. A system subdivision is structured like the directory tree of a personal computer, or more like an upside down tree or the root system of a tree. I have only shown the major blocks, assemblies and subassemblies, each of which would have an associated parts list of basic reference designated parts. As you go down the levels of the system subdivision the reference designation prefixes are added on. If you only have one unit in your product then you can drop the number (unit number).

A resistor R1 in the final or top assembly of a single unit product would be 1R1 (R1), while resistor R1 in the assembly 1A2A1A2 (A2A1A2) would use that as the prefix and thus the complete reference designator would be 1A2A1A2R1 (A2A1A2R1).

Lest you think that this unit numbering system is only used by the government, which includes the DoD, DoE, FAA, FCC, and NASA you would be wrong. As I recall looking at the service/maintenance manual for the old HP spectrum analyzer model 141T mainframe and IF plug-ins, they used this system. As did the old HP network analyzer model 8410C. And that Channel 41 TV transmitter, designed and produced by Amperex, that I babysat also used the Unit Numbering Method. So be aware, it’s out there.

The ASME Y14.44 standard has Appendix A that talks about the Block Numbering Method. In this method a block of numbers is allocated to each unit or major assembly. “The basic reference designation is the complete reference designation; no unit numbers or assembly prefix reference designations are used”. This method seems to be the method of choice, supposedly because it seems so simple, but it doesn’t work in many cases and it needs to work in all cases.

The first paragraph of ASME Y14.44, Appendix A has this statement, “The unit numbering method has significant advantages over the block numbering method. Accordingly, it is preferred that the unit numbering method be used for all units of new design, even though this may result in a mixture of numbering methods within the equipment”.

Block Numbering Method Comments

- How do you reference designate assemblies?

- How do you reference designate the gold plated fingers on a PCB of a printed board assembly (PBA)?

- How do you reference designate the mating connector of a PBA

- That has gold plated fingers?

- That has a plug connector?

- How do you reference designate a mains power cord with a male plug on one end and a female plug on the other end?

- How do you reference designate a part that already has connector reference designators marked on the part?

- How do you reference designate the mating connectors of a part that already has connector reference designators marked on the part?

- Given that you have a part with two connectors, one reference designated J1 and the other reference designated P1, how do you reference designate the mating connectors?

Experience I have had with ECAD/EDA systems include:

PADS (Personal Automated Design System, or something like that) when it was an independent company based in Massachusettes. I only used the schematic capture part of it as the small company I worked for had two guys that did the board layout work.

A very large avionics company I worked for had Mentor Graphics DxDesigner for schematic capture and Board Station for board layout. There was a whole department that did PCB layout while the engineers did the schematic capture.

I used Mentor Graphics PADS later when I worked for a very small company and I did both schematic capture and board layout.

The printed circuit board assembly house I worked for had Altium Designer that the head engineer was always using. I would use it to look over the Gerber files from customers in order to properly order the PCBs for the product. I never got a chance to do any schematic capture or board layout with this software program.

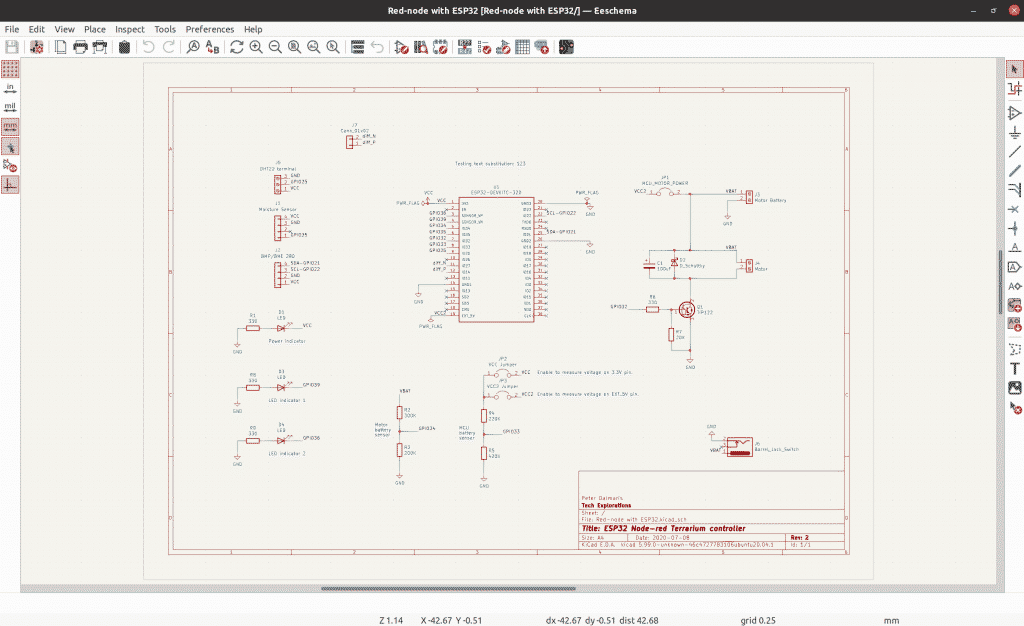

Having known about KiCad previously I had the IT guy at the PBA house, mentioned above, download KiCad in order that I could use KiCad’s GerbView program to look over Gerber files, because the head engineer was always busy using the only company’s copy of Altium. I have used KiCad personally to do several schematic diagrams and now that KiCad version 5 has been released, as of 2018-07-22, I plan on several projects that include PCBs.

See Appendix E for an anomalous situation with KiCad dealing with suffix letters. There may be other EDA programs that suffer this also, but I am not aware of them.

See Appendix F for scenario questions and answers. This list is not exhaustive and if you have a scenario question please let me know and I will try to answer it and add it to this list.

Jump to another article

1. Reference designators for electrical and electronics parts and equipment

2. Appendix A: A list of pertinent applicable standards

3. Appendix B: Class Designation Letters

4. Appendix C: List of nonconforming class letters

5. Appendix D: System subdivision

6. Appendix E: KiCad Anomalous Handling of Suffix Letters.

7. Appendix F: Scenario Questions and Answers.

About the author

The articles in this series are written by Lawrence W. Joy (Larry)

[email protected]

Michigan USA.

We publish fresh content each week. Read how-to's on Arduino, ESP32, KiCad, Node-RED, drones and more. Listen to interviews. Learn about new tech with our comprehensive reviews. Get discount offers for our courses and books. Interact with our community. One email per week, no spam; unsubscribe at any time