Data Acquisition and Control guide series

01

What is Data Acquisition and Control?

In this lesson, I will discuss In this lecture, I discuss the concepts of data acquisition and control as they are essential to everything you're about to learn.

Hi, thanks for stopping by! Just letting you know that we are currently working on this page. You may notice incorrect links and lots of typos. We expect to buff and polish within a few days.

The term "data acquisition" refers to software and hardware that we use to measure the physical characteristics of real world processes.

With the term "control", we refer to the process of making changes to specific attributes in the real world.

I use the words "real world" to emphasize the fact that data acquisition and control deal with processes outside of a computer.

We use sensors to convert real world signals to binary code so that computers can store and process them. And we use actuators (motors, relays, etc.) to control specific attributes in the real world.

Data acquisition and control technologies are very common in industrial settings, such as factories and warehouses. Over the last 20 years, data acquisition and control is a common part of our everyday experience. Modern cars are filled with computers and sensors, collecting data and making decisions that control every aspect of engine and subsystem operations. Homes are also becoming automated using similar technologies.

In this lesson, I'll provide a broad definition of data acquisition and control and give some examples.

By the end of this lesson, you have a better understanding of the related concepts and their importance in modern engineering.

What is Data Acquisition?

Let's start with data acquisition.

Data acquisition is the process of sampling and recording of real world signals.

To record a real world signal in a computer memory, the signal must first be converted to a compatible digital format.

Sampling, conversion, filtering, amplification, processing, and recording are the basic elements of data acquisition.

A simple example of a real world signal is temperature. We can capture temperature with the help of a sensor. Common temperature sensors convert temperature into voltage. The capturing device is able to read the voltage and convert it into a binary number that is then stored in a computer memory.

Why is this useful?

Because of what computers can do with this binary number, which, remember, represents the original real world signal.

Computers can use this number to control actuators. Actuators are devices that produce some kind of work. Examples of actuators are motors, industrial ovens, relays, and solenoids.

Computers can also rapidly analyze large numbers of real world signals. The result of the analysis allows us to understand some aspect of our world. A revolutionary new technology that depends on large data set analysis is artificial intelligence and machine learning. The result of these technologies is computers that can make decisions. From washing machines to self-driving cars and Mars rover explorers, smart machines depend on the data acquisition, analysis, and control processes.

What is Control?

Control is the objective of a control system.

Control is what a control system does.

A control system is a computer that is designed specifically to control one or more actuators such as motors, valves, and hydraulic brakes. In almost every case, a control system regulates an actuator based on some kind of input and logic.

Logic is implemented via a programing language. Input derives from a sensor and/or from a human user via a user interface.

I cannot think of a control system that does not contain some kind of input.

Control systems are extremely important in modern life. Control systems ensure that an elevator will take you to the correct floor, that your car engine will inject and burn fuel at the exact right moment to get maximum torque and efficiency, and that your garage door does not close on a person that happens to be standing at the wrong place and time.

Control systems are abundant in factories, office buildings, motorways, and airports.

Control systems work in tandem with data acquisition systems. In fact, data acquisition and control capabilities are integrated into hardware that does both very well. Let's look at some examples.

DaQ examples

A common application of data acquisition and control system is the regulation of environmental conditions of a room. Thermostats are commonly used for this. A thermostat contains a temperature sensor to measure the temperature of the air around it. Thermostats are connected to a heating and cooling device such as a heater or air conditioner.

The user can set the thermostat to the desired temperature and it controls the air conditioner so that the actual air temperature matches the select temperature. Smart thermostats also contain memory. This allows them to record activity in the controlled room, learn user preferences, and control the heating, ventilation, and air conditioning system to achieve an energy efficient yet comfortable room without explicit instructions from the user.

Conveyor belts can move all kinds of objects from one place of a warehouse to another. Airport luggage management, Amazon warehouses and distribution facilities, computer assembly lines, even massive amounts of iron ore and coal are moved on conveyor belts.

With a modern data acquisition and control system, a simple conveyor belt is transformed into a smart product highway. Optical scanners and RFID readers are used so that the conveyor belt controller knows exactly where a specific object is.

Motorized gates are then used to divert an object into alternative routes. All of this is done in a deterministic way so that the flow of products through the conveyor belt system is constant. And the travel time for any of the thousands of objects on it is predictable within seconds.

Modern e-commerce and manufacturing would not be possible without modern conveyor belt systems powered by modern data acquisition and control systems.

Here's an example from an experiment on the Control Design website. This experiment compared the application of an Arduino and an industrial PLC control system as DaQ technologies.

The setup is a typical closed loop control system that contains a water flow sensor and a water flow valve.

The water that enters the system from the outside world comes in at a variable rate. The control system's objective is to ensure that the water that comes out of the system has a specific flow that is set by the user. This can be achieved by measuring the real world flow of the water that enters the system using a flow meter and then using a control valve to increase or decrease the flow so that it matches the value set by the user.

In this experiment, the exact same outcome was achieved by the Arduino controller and by the PLC. As I'll discuss later, there are various technologies on which data acquisition and control systems can be based, each with its own advantages and disadvantages. In this specific experiment, the Arduino solution actually required more complicated hardware interfaces to allow it to connect with a flow meter and evolve, as well as a slightly more complicated implementation for the software.

The PLC is already engineered to be able to work with industrial sensors and actuators using domain specific languages such as ladder logic and function block diagrams. More about this later.

Here's another example.

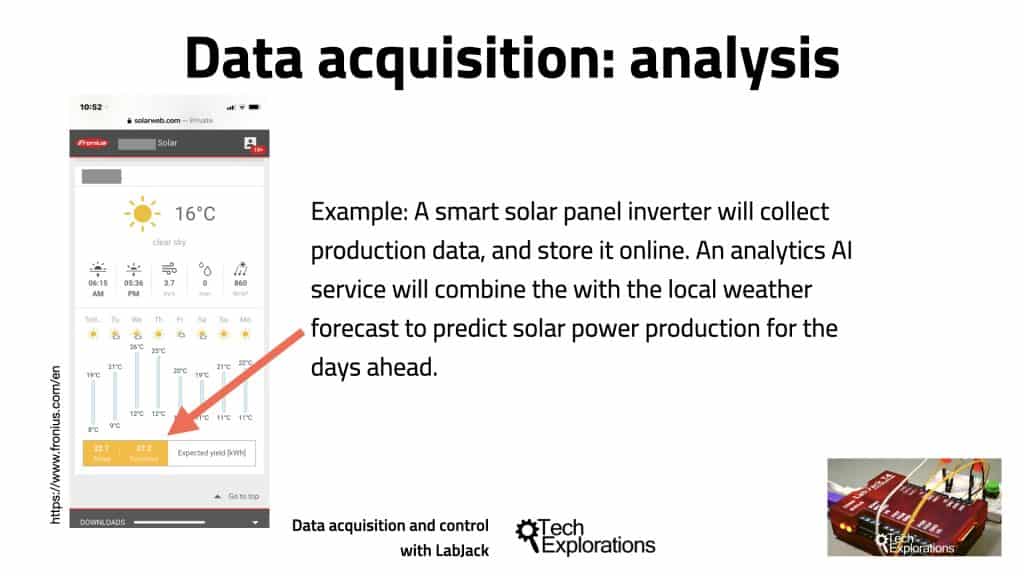

Above you can see a screenshot from my phone. I have an array of solar panels on my roof connected to a smart inverter from a company called Fronius. The inverter collects electricity production data from the panels and sends them to Fronius.

Fronius knows my location and uses data from the Bureau of Meteorology to learn about the amount of sun that my panels might get the next day.

By combining historical energy production data and the weather forecast, Fronius can give me a reasonably accurate prediction of how much energy my solar panels might produce the next day. I use this information to decide whether to run heavy loads like the clothes dryer or the dishwasher during the day or leave it for off-peak.

This has saved me hundreds of dollars every year.

Here's one last example of how real world data analysis is used in everyday life.

All modern cars contain multiple controlled units, which are simple computers. Each one is purposed to actively control an aspect of a car's operations.

For example, the engine control unit (ECU) is responsible for collecting real time data from the engine, such as the position of the foot throttle, the current RPMs, fuel volume flow, and the temperature of the engine to decide the exact air and fuel mix in real time.

It will also use stored data about my driving style and will enforce limits set by the manufacturer in order to prevent excessive wear and tear and reduce emissions.

Other control units in the car control the entertainment system, the powertrain and suspension characteristics, and much more, just to name a few here.

DaQ tools

Data acquisition and control depends on hardware that is specialized for these tasks.

Although some sensors are plug and play, most high quality sensors on the market require an interface in order to capture and record meaningful data.

In industrial and commercial settings and, increasingly, at home, schools, and businesses, using the regular computer is not practical.

They are too big and not reliable enough. They are fragile. They can't interface to industrial sensors and actuators without expensive interfaces. And they can't fulfill strict real time requirements.

DaQ with microcontrollers

In almost every reasonable data acquisition and control scenario, we use hardware that is designed for this specific purpose.

Micro controllers such as the Arduino, the Raspberry Pi, and the ESP32 are how many of us learn programmable electronics. We learned how to use micro controllers to read sensors and control motors. So, they are increasingly the first technology that we evaluate when we have a data acquisition and control problem to solve.

Micro-controllers are easy to program and to connect the devices that we find in retail and electronics shops.

But this is not the hardware that you'll find in a factory.

Also, the environment in which we tend to learn how to use the Arduino is very different to that in a factory. Home temperatures tend to fluctuate within a few degrees. Electrical noise is low. Dust, moisture, and other contaminants are also low. What works well in a home might not work well or at all in a factory without consideration of all of the above.

There is also the issue of the software. The Arduino owes its success partially on the abundance of libraries and its programing environment that makes it easy to adapt to the needs of a personal project. Industrial data acquisition and control are very different in terms of the kinds of problems that need to be solved. Arduino libraries may be useful for hobbies and projects, but need a lot of rework to fit in an industrial setting.

All that said, there are now many Arduino powered platforms for industrial automation and control. An example is the Controllino, which is an industry grade PLC, Programmable Logic Controller, that is compatible with the Arduino ecosystem.

Controllino can be connected directly to any device that a regular PLC can. With platforms like the Controllino, it is possible to have the best of both worlds, Arduino and PLC.

DaQ with Programmable Logic Controllers

I have mentioned the term PLC a few times in this light, but I haven't explained what it is.

Let's take a look at that.

A PLC or Programmable Logic Controller is an industrial computer control system that is specifically designed for data acquisition and control operations in an industrial environment.

PLCs are expected to run for many years of continuous service without failure.

Externally, a PLC is made to be tough so that it can operate in harsh environments. These are environments with a lot of electrical noise, often strong mechanical shocks or vibration with airborne dust and big variations in temperature and humidity.

PLC's have numerous inputs and outputs so they can be connected to all kinds of sensors and actuators.

I use the word actuator to mean any device that can act on its environment, including those that produce movement and those that change environment conditions, like temperature and illumination.

Typical sensors, you'll find connected to a PLC include photoelectric sensors, fluid flow, temperature, and pressure sensors, torque sensors, counters, and encoders.

Typical actuators you'll find connected to a PLC include hydraulic linear actuators, electric rotary actuators, heaters and coolers, servos, relays, and fluid valves. PLCs often utilize real time programing languages and operating systems to ensure that the operations are completed within accurately predictable time frames.

Further, tolerance and recovery can also be integrated in the design of the systems so that impact of a fault in the operation of a facility is limited. PLCs can be installed with battery backups and redundancies to increase the full tolerance.

All these capabilities mean that PLC is an excellent choice for data acquisition and control in an industrial setting.

DaQ with Computer-Aided Measurement and Control

Next, let's have a look at another example of hardware used in data acquisition.

In the slide above you can see an example of a Computer-Aided Measurement and Control system or CAMAC pictured here.

I decided to include CAMAC in this discussion because it's a representative of a hyper-specialized system designed for applications with very high data acquisition rates.

These are the kinds of rates that you'll find in large science experiments, such as particle detectors and nuclear and particle physics labs.

The newer versions of this technology and supporting protocol are capable of transferring 24 bit data words every 450 nanoseconds or even faster.

They're really, really fast.

DaQ with LabJack

And, of course, there's LabJack.

LabJack is another example in the space of data acquisition and control.

In my opinion, LabJack sits in the middle between regular micro-controllers and industrial PLCs.

LabJack is ruggedized so that it can operate in a data center or in a reasonably noisy and dusty factory floor.

And it's also suitable for mobile independent applications.

It can work with autonomy.

It can be controlled remotely.

Similar to PLCs, it can communicate directly with industrial devices using dozens of input/output ports and can be programed with a variety of traditional and graphical programing languages.

I'll finish my mention to LabJack here because I have dedicated the next lesson to it.

"Data Acquisition and Control" series

Learn Data Acquisition and Control with LabJack

With this video course, you will learn how to use the LabJack device to perform data acquisition and control (DaQ) operations.

LabJack was designed to be robust and reliable, to work autonomously in harsh environments for a long period of time, and to have a lot of input/output ports able to connect to a huge range of sensors and actuators.

Jump to another article

Last Updated 4 years ago.

We publish fresh content each week. Read how-to's on Arduino, ESP32, KiCad, Node-RED, drones and more. Listen to interviews. Learn about new tech with our comprehensive reviews. Get discount offers for our courses and books. Interact with our community. One email per week, no spam; unsubscribe at any time