KiCad 6 Guide series

What is a PCB?

An overview of the components of a PCB, how a PCB looks, and the terminology that we use.

My earliest experiences with PCBs

As a child, I remember that my interest in electronics grew from admiration of what these smart engineers had come up with to curiosity about how these things worked. This curiosity led me to use an old screwdriver that my dad had left in a drawer (probably after fixing the hinges on a door) to open anything electronic with a screw large enough for the screwdriver to fit in.

A record player, a VCR, a radio; all became my "victims." I am still amazed that a charged capacitor didn't electrocute me. At least, I had the good sense to unplug the appliances from the mains. Inside those devices, I found all sorts of wondrous things: resistors, transformers, integrated circuits, coils, and power supplies.

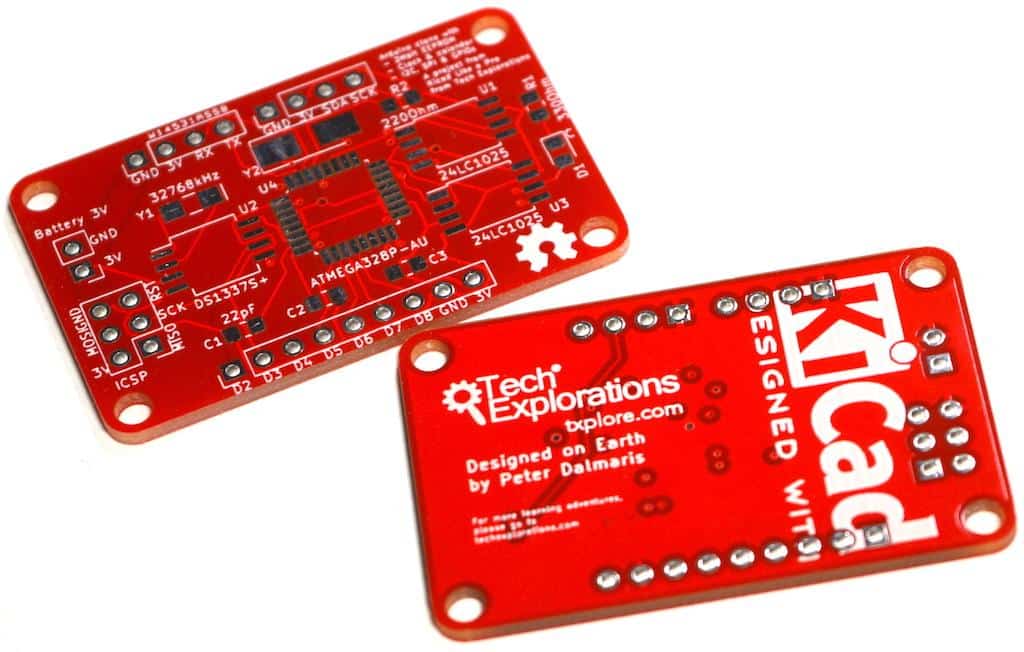

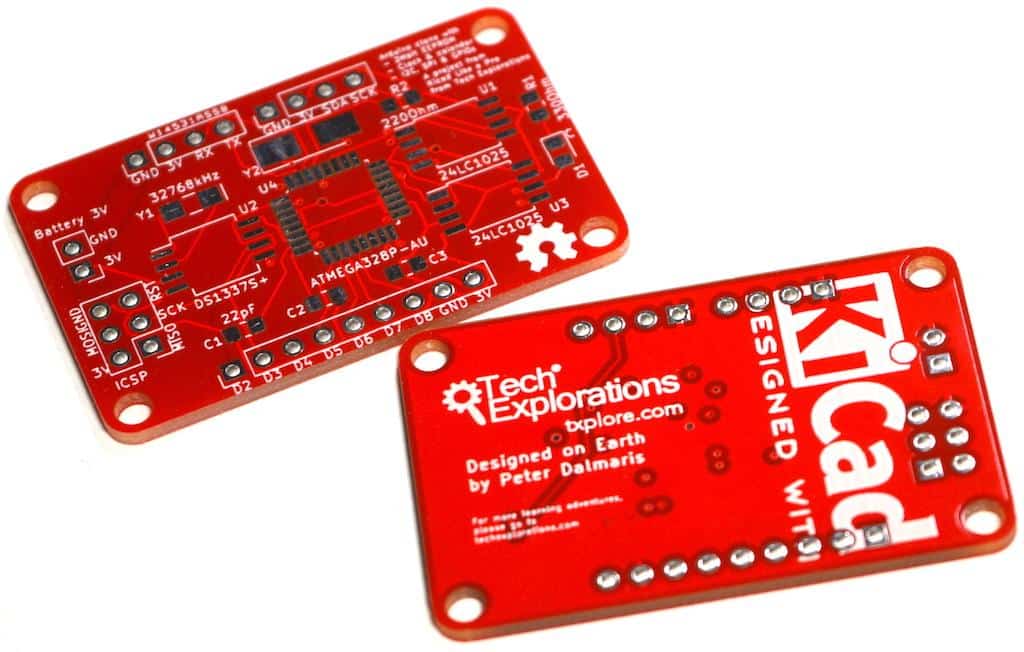

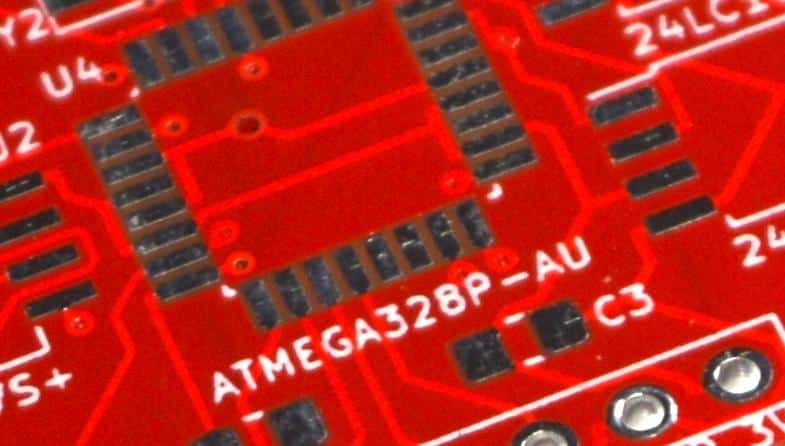

Engineers had attached those things on small green boards, like the one in Figure 1.1.1. This is an example of a printed circuit board, or PCB, for short.

Figure 1.1.1: The top side of a printed circuit board.

Components of a PCB

Let's look at the components of a PCB, what a PCB looks like, and the terminology that we use. The example PCB is one I made for one of my courses (Figure 1.1.1).

The top side of the PCB is the side where we place the components. We can place components on the bottom side, too.

In general, there are two kinds of components: through-hole or surface-mounted components. We can attach through-hole components on the PCB by inserting the leads or the pins through small holes and using hot solder to hold them in place. In the example pictured in Figure 1.1.1, you can see several holes to insert the through-hole component pins. The holes extend from the top side to the bottom side of the PCB and are plated with a conductive material. This material is usually tin, or as in the case of the board in the image, gold. We use solder to attach and secure a component through its lead onto the pad surrounding the hole (Figure 1.1.2).

Figure 1.1.2: A through-hole component attached to a PCB.

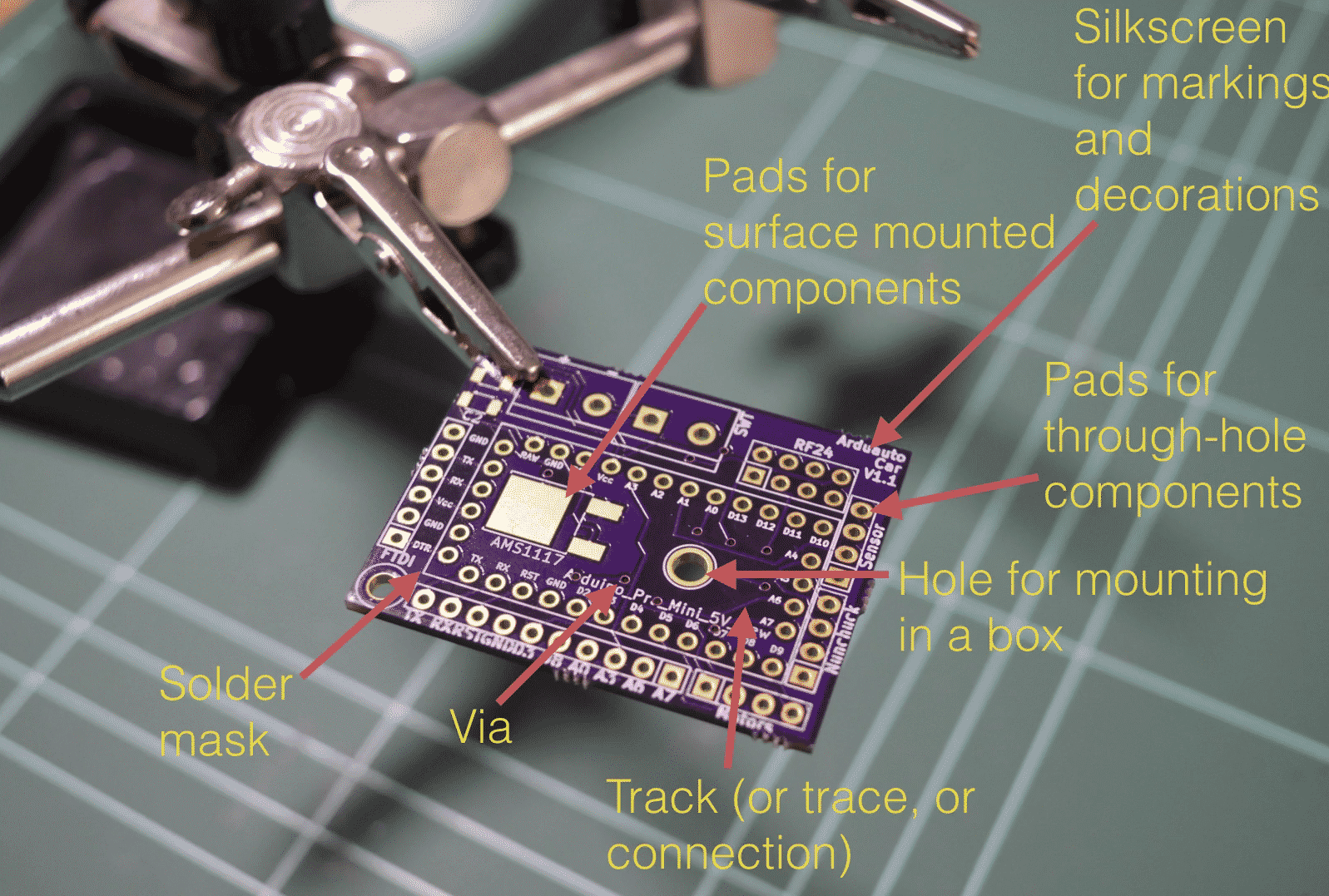

If you wish to attach a surface-mounted component, then instead of holes, you attach the component onto the surface of the PCB using tin-plated pads. You will use just enough solder to create a solid connection between the flat connector of the component and the flat pad on the PCB (Figure 1.1.3).

Figure 1.1.3: A surface-mounted component attached to a PCB.

Next is the silkscreen. We use the silkscreen for adding text and graphics. The text can provide helpful information about the board and its components. The graphics can include logos, other decorations, and useful markings.

Figure 1.1.4: The white letters and lines is the silkscreen print on this PCB.

In Figure 1.1.4, you can see here that I've used white boxes to indicate the location of various components. I've used text to indicate the names of the various pins, and I've got version numbers up there. It's a good habit to have a name for the PCB and things of that sort. Silkscreen goes on the top or the bottom of the PCB.

Sometimes, you may want to secure your PCB onto a surface. To do that, you can add a mounting hole. Mounting holes are similar to the other holes in this board, except they don't need to be tinned. You can use a screw with a nut and bolt on the other side to secure the PCB inside a box.

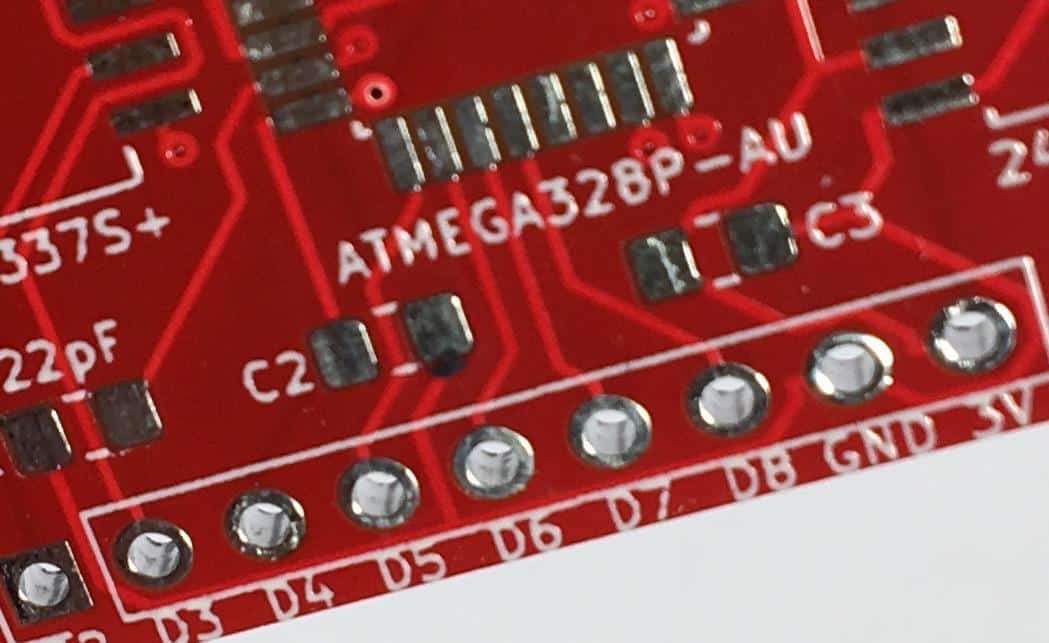

Next are the tracks. In this example (Figure 1.1.5), they look red because of the color of the masking chemical used by the manufacturer.

Figure 1.1.5: The bright red lines connecting the holes are tracks.

Tracks are made of copper, and they electrically connect pins or different parts of the board. You can control the thickness of a track in your design. You can also refer to a "track" as a "trace."

Notice the small holes that have no pad around them? These are called 'vias.' A via looks like a hole but is not used to mount a component. A via is used to allow a track to continue its route in a different layer. If you're using PCBs with two or more layers, you can use vias to connect a track from any one of the layers to any of the other layers. Vias are handy for routing your tracks around the PCB.

The red substance that you see on the PCB is the solder mask. It does a couple of things. It prevents the copper on the PCB from being oxidized over time. The oxidization of the copper tracks negatively affects their conductivity. The solder mask prevents oxidization.

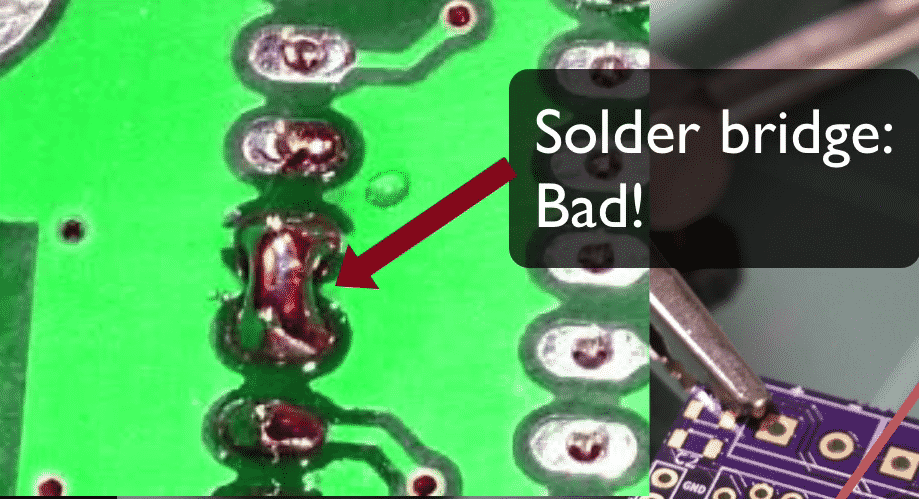

Another thing that the solder mask does is to make it easier to solder by hand. Because pads can be very close to each other, soldering would be complicated without the solder mask. The solder mask prevents hot solder from creating bridges between pads because it prevents it from sticking on the board (Figure 1.1.6). The solder mask prevents bridges because the solder cannot bond with it.

Figure 1.1.6: A solder bridge like this one is a defect that a solder mask can prevent.

Often, the tip of the solder, the soldering iron, is almost as big or sometimes as bigger than the width of the pads, so creating bridges in those circumstances is very easy, and a solder mask helps in preventing that from happening.

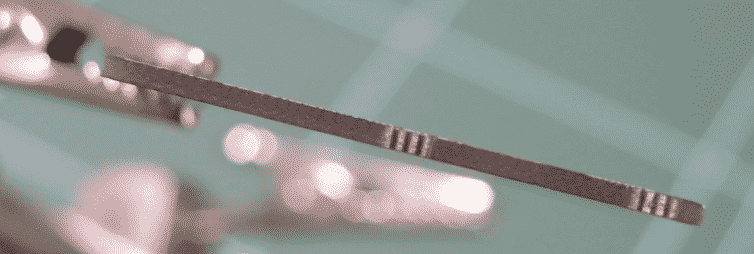

In Figure 1.1.7 you can see an example of the standard 1.6mm thick PCB.

Figure 1.1.7: This PCB has a thickness of 1.6mm, and is made of fiberglass.

Typically, PCBs are made of fiberglass. The typical thickness of the PCB is 1.6 millimeters. In this closeup view of a PCB picture (Figure 1.1.8), you can see the holes for the through-hole components. The holes for the through-hole components are the larger ones along the edge of the PCB. Notice that they are tined on the inside, electrically connecting the front and back.

Figure 1.1.8: A closeup view of the top layer.

In Figure 1.1.8, you can see several vias (the small holes) and tracks, the red solder mask, and the solder mask between the pads. In this closeup, you can also see the detail of the silkscreens. The white ink is what you use in the silkscreen to create the text and graphics.

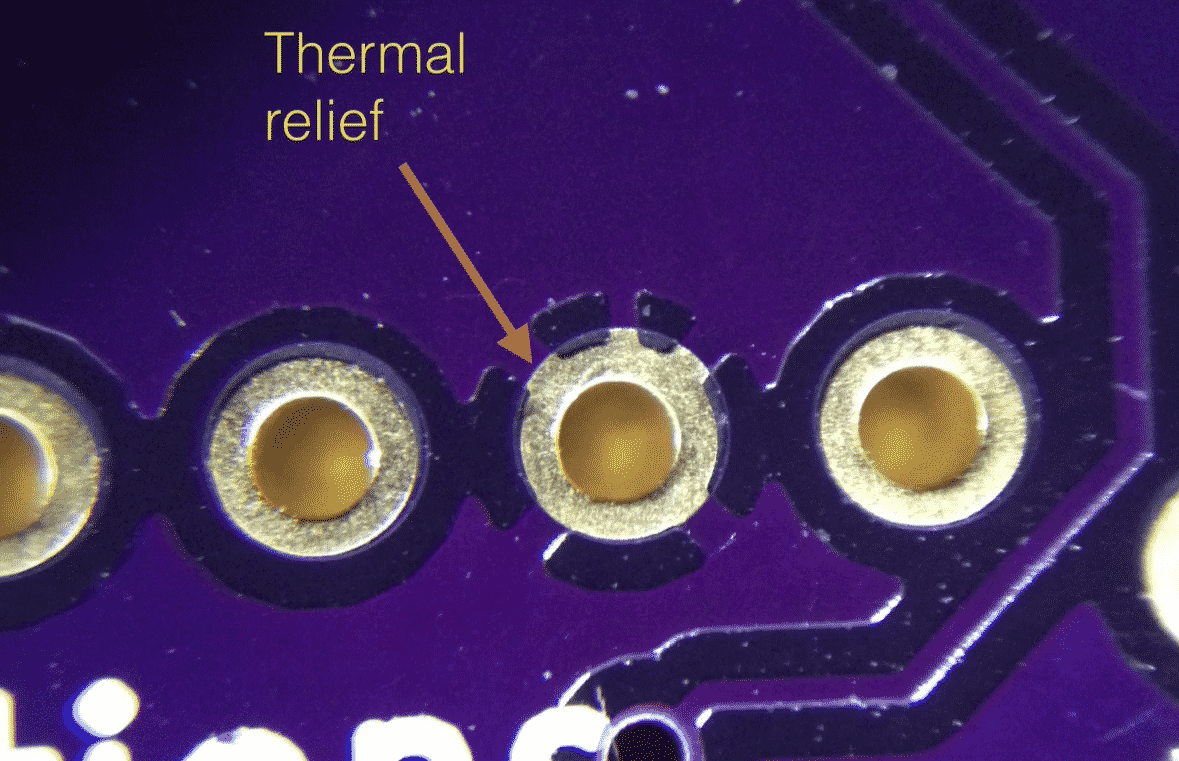

Figure 1.1.9 is interesting because it shows you a way to connect grounds and VCC pads to large areas of copper, which is called the copper fill.

Figure 1.1.9: Thermal relief connects a pad to a copper region.

In Figure 1.1.9, the arrow points to a short segment of copper that connects the pad to a large area of copper around it. We refer to this short segment of copper as a 'thermal relief.' Thermal reliefs make it easier to solder because the soldering heat won't dissipate into the large copper area.

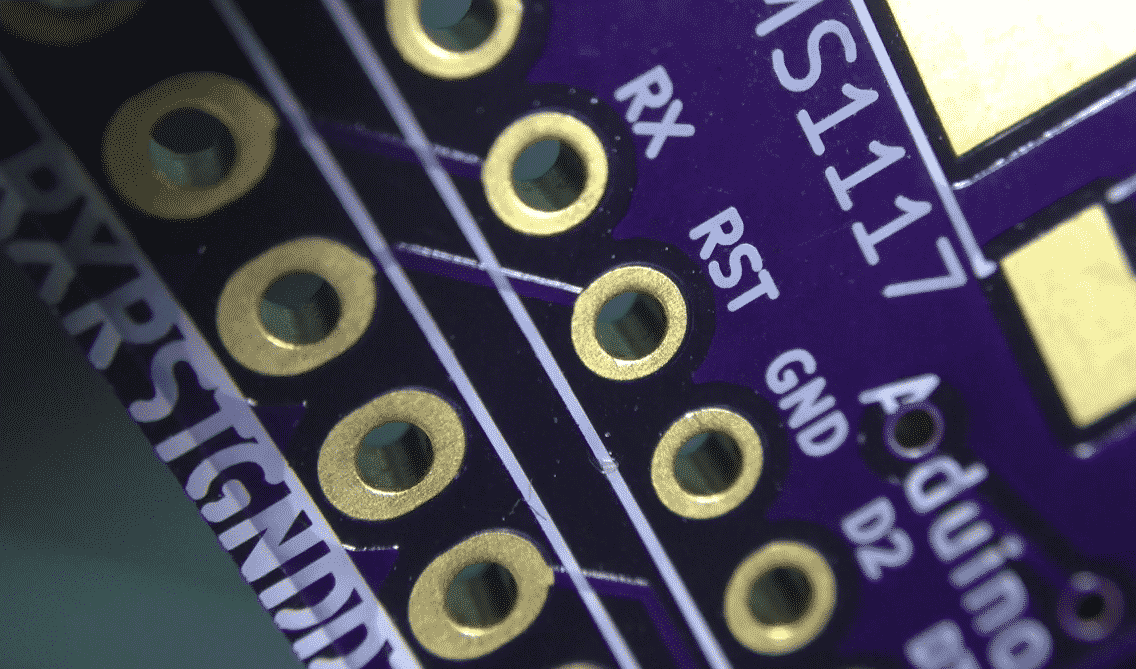

Figure 1.1.10 gives a different perspective that allows us to appreciate the thickness of the tracks.

Figure 1.1.10: The plating of the holes covers the inside of the hole and connects that front end with the back end.

Notice the short track that connects the two reset holes (RST)? The light that reflects off the side of the track gives you an idea of the thickness of that copper, which is covered by the purple solder mask.

In this picture, you can also see a very thin layer of gold that covers the hole and the pad and fills the inside of the hole. This is how you electrically have both sides of the hole connected.

Instead of gold plating, you can also use tin plating to reduce manufacturing costs.

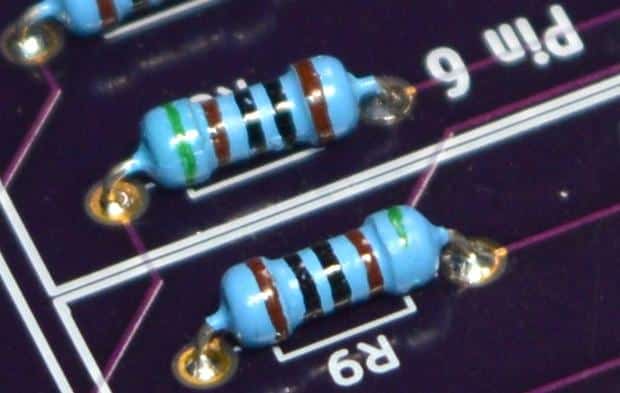

Figure 1.1.11: A detail of this example board at 200 times magnification.

The image in Figure 1.1.11 was taken at 200 times magnification. You can see a track that connects two pads and the light that reflects off one side of the track.

Ready to learn KiCad?

Learn the world's favourite open-source PCB design tool with the world's most comprehensive course

KiCad Like a Pro, is available as a video course or as an eBook.

Choose the version that fits best with your style of learning, or get both to get the full benefit of the video demos plus the details of the eBook.

When you complete KiCad Like a Pro, you'll be able to use KiCad to design and manufacture multi-layer PCBs with highly integrated components and a professional-looking finish.

Work through five projects that give many opportunities to learn and practice all of KiCad's important features.

KiCad Like a Pro contains full sections dedicated to PCB and design principles and concepts. These ensure that you will master the fundamentals so that your PCB project are awesome.

If you are someone who is interested in designing PCBs using KiCad, or moving to KiCad from another CAD application, then KiCad Like a Pro, the video course and eBook, is for you.

Jump to another article

KiCad 6 Guides

0. Why learn KiCad?

1. What is a PCB?

2. The PCB design process

3. PCB fabrication

4. Get KiCad for your operating system

5. An example KiCad project

6. KiCad Project Manager (main window)

7. Overview of the individual KiCad apps

8. KiCad Paths and Libraries

9. Create a new KiCad project from scratch

10. Create a new KiCad project from a template

11. KiCad 6 on Mac OS, Linux, and Windows

12. Major differences between KiCad 6.0 and 5.0

13. KiCad Schematic symbols

14. PCB key terms

Contributed articles

Last Updated 1 year ago.

We publish fresh content each week. Read how-to's on Arduino, ESP32, KiCad, Node-RED, drones and more. Listen to interviews. Learn about new tech with our comprehensive reviews. Get discount offers for our courses and books. Interact with our community. One email per week, no spam; unsubscribe at any time